Isar Aerospace unveils progress on Aquila engine development

We believe that building rockets is about taking risks, failing, learning from failures and iterating fast. In our hardware-rich development, we allow ourselves no more than 4 weeks for test article iterations, including data analysis, design adjustments and manufacturing.

124 hotfires in 1 year of testing

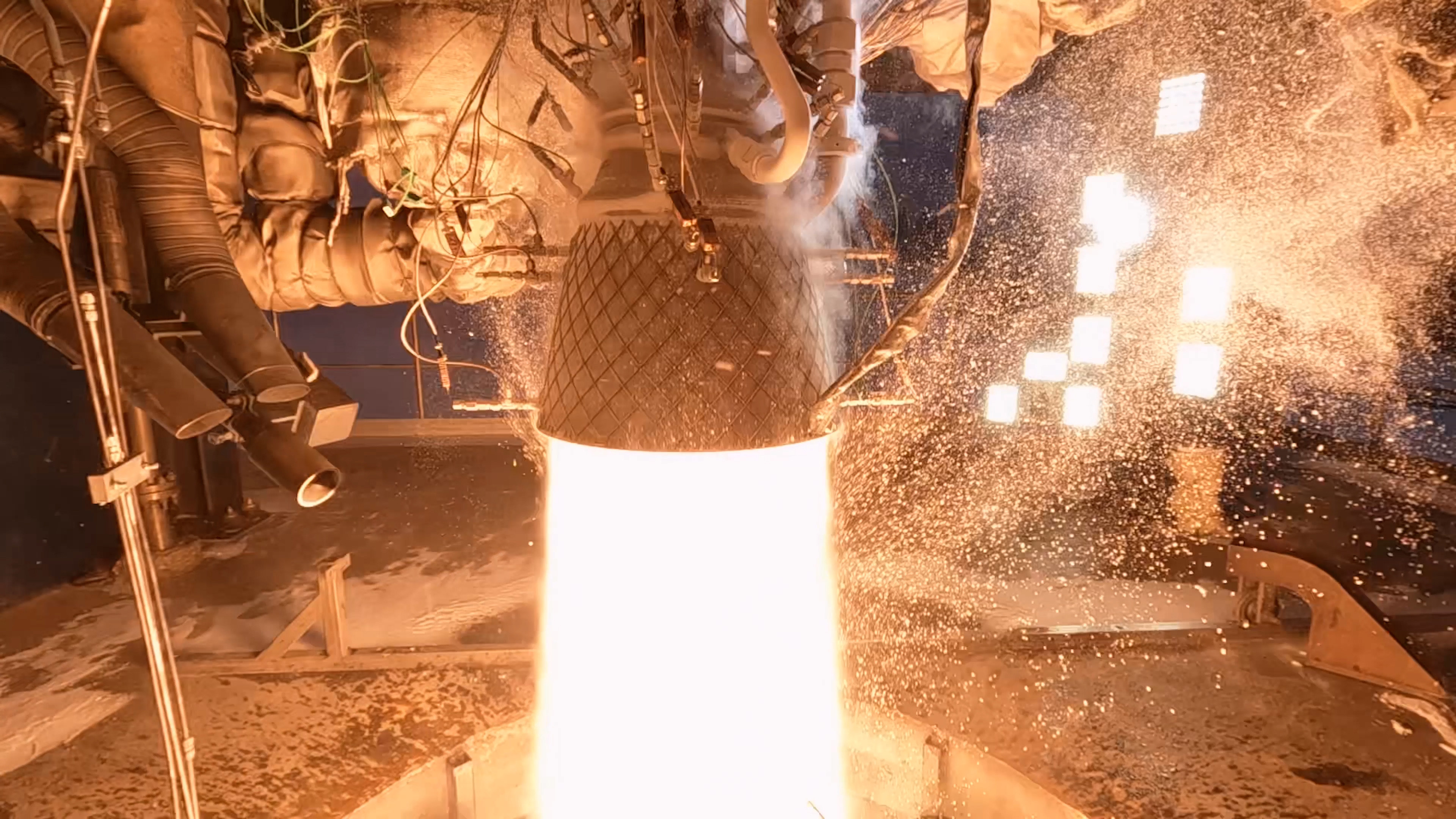

In the last 12 months, we have been working relentlessly on the development of our Aquila engine – fully designed and built in-house, and tested at our engine test site in Esrange, Sweden.

We ran 719 test sequences, both on the subsystems of the engine and the integrated system. With 124 hotfires in our books, we are tremendously excited to share the progress our team has achieved.

Throughout the last year we reached nominal ignitions, chamber pressures and performance while optimizing the design for high manufacturing throughput. We believe that scalability in manufacturing is one of the biggest challenges for the space industry: going from single satellites and a few rockets to thousands of satellites and rockets. Our approach to automated production processes thus, is a core element of our engine development.

Check out the video of the test via YouTube here: https://youtu.be/rDoNX72a0HM

Aquila's special features

Designed and manufactured entirely in-house, our gas generator cycle engine runs on cryogenic liquid oxygen and propane for a powerful, clean propulsion. Powering the Aquila engine is also our fully-inhouse developed turbopump that converts the gas generator exhaust gas pressure efficiently into rotational energy. The connected pumps provide high-pressure propellants to the combustion chamber. Running at multiple tens of thousands of rotations per minute, our turbopump assembly turned out even more efficient than initially predicted.

High-speed iteration

From test results, analysis, and adjustments, back to testing a new test article, we allow ourselves no more than 4 weeks. How is this even possible?

Vertical integration at the core, three factors are essential to ensure high speed iteration: Firstly, we are operating our own test facilities. Our component test site close to the production in Bavaria, Germany enables quick checks in a secure environment. At our engine test site in Sweden, we have full testing availability for the in-house development. This gives us the highest flexibility and utmost speed in testing. Secondly, our full in-house production with a high degree of automation allows for maximum efficiency and speed in iterations. And thirdly, using cutting-edge technologies like additive manufacturing, we 3D-print key elements of our engine from high performance metals to enable high design flexibility and part reduction with shortest lead times.

Developing our engine, we follow a three-step approach of subsystem development, integrated system testing and conclude the development with flight hardware production.

"We are excited that we achieved major progress in the development and our hard work has paid off. Having full control over our systems and owning the engine technology will be an essential element in our journey to orbit," says Josef Fleischmann, CTO and COO at Isar Aerospace.

"One of our guiding core values at Isar is "Push The Boundaries" – we thank our team for living up to this every day, to bring the Aquila engine to life. Their incredible energy, dedication and know-how brought us here and enabled us to develop a rocket engine entirely from scratch!" says Can Araz, VP of Propulsion at Isar Aerospace.

About Isar Aerospace

Isar Aerospace, based in Ottobrunn/Munich, develops and builds launch vehicles for transporting small and medium-sized satellites as well as satellite constellations into Earth’s orbit. The company was founded in 2018 as a spin-off from Technical University Munich. Since then, it has grown to more than 300 employees from more than 40 nations with many years of hands-on rocket know-how as well as experience within other high-tech industries. The company is privately financed by former SpaceX VP Bulent Altan as well as world-leading investors including Airbus Ventures, Apeiron, Earlybird, HV Capital, Lakestar, Lombard Odier, Porsche SE, UVC Partners, and Vsquared Ventures.

Find more information via: https://www.isaraerospace.com

Press contact Isar Aerospace

Tina Schmitt

E tina.schmitt@isaraerospace.com